SEIL's state of the art fully automated Continuous Rolling Mill has a capacity of manufacturing 0.25 Million TPA of 'SIMHADRI TMT' branded rebars. The Rolling Mill produces TMT (Thermo Mechanically Treated) rebars based on the Tempcore Process, a quench and self-tempering process invented and developed by the CRM Group (Cente de Recherches Métallurgiques) of Belgium. The same quenching process is also used by Tata Steel & Visakhapatnam Steel Plant in India and by companies like Arcelor Mittal and Gerdau abroad.

Process

The 100x100 or 110x110 billets of specified length from the continuous caster are transferred to the rolling mill by way of the Hot Charging conveyor. The entry temperature of the billet to the rolling mill is continuously monitored by Pyrometer and the billets having a temperature lower than the specified temperature are rejected before entry into the roughing mill.

The Billets are rolled a in fully automated continuous rolling mill having 20 Passes. Cobble shears are provided after the 8th Pass and the 12th Pass for front end cutting, back end cutting and cobble cutting. Loppers are present in the finishing area for tension free rolling of bars to give uniform stock during rolling.

The Finishing End rolls ribs are cut in a three axis CNC Rib cutting machine to maintain the rib uniformity and angle for good pull out strength properties uniformly throughout the length of the bars being rolled.

The hot rolled rebars are passed through the quenching box designed using the TEMPCORE process. The water temperature and the pressure are maintained by monitoring flow, temperature using PID gain controller and the use of variable frequency driven motor pumps. The quenching is done by soft water. The equalising temperature is maintained uniformly with the help of automation.

The bars are cut by using flying shear and discharged on to a 66 meter moving rake cooling bed. The bars are cooled on the moving rake to around 70oC and automatically transferred onto the cold shear conveyor and cut to a 12 meter length with tolerance of ±50 MM. The Bars are transferred automatically to the automated bundling stations for bundling and collection on to the collecting platform after the ends are spray painted to avoid corrosion on the cut surfaces. The bundles are lifted by magnetic overhead cranes for stacking.

The quality of the rolling process is maintained by state of the art automation systems, using SIEMENS PLCs, ABB DC and VFD Drives. IBA Software is used to closely monitor events in simultaneous 0.1 millisecond gaps across the rolling process.

The rebars are tracked in the mill by hot metal detectors. The bar temperature is monitored by temperature scanners. Various parameter trends are tracked and stoared. Level 1.5 automation is used for reporting and data acquisition. CCTV cameras with recording are installed to view the rolling process and the manpower involved.

The Quality Assurance Plan (QAP) is ensured by the use of Spectrometer, UTM testing machine, Extensometer, Bend & Rebend equipment and software for plotting and printing the stress strain graph and 0.2 % proof test graph.

The above process controls enable the production of rebars of grade Fe500, Fe550, Fe500D, Fe550D and HSCRM (IS and BS standards for high strength bars) for ductile bars which are highly recommended for earthquake zones. The conformance for both the standards ensures superior strength, durability and ductility required for modern construction and techniques. SEIL also produces made to order grades of rebar for specific requirement by end users.

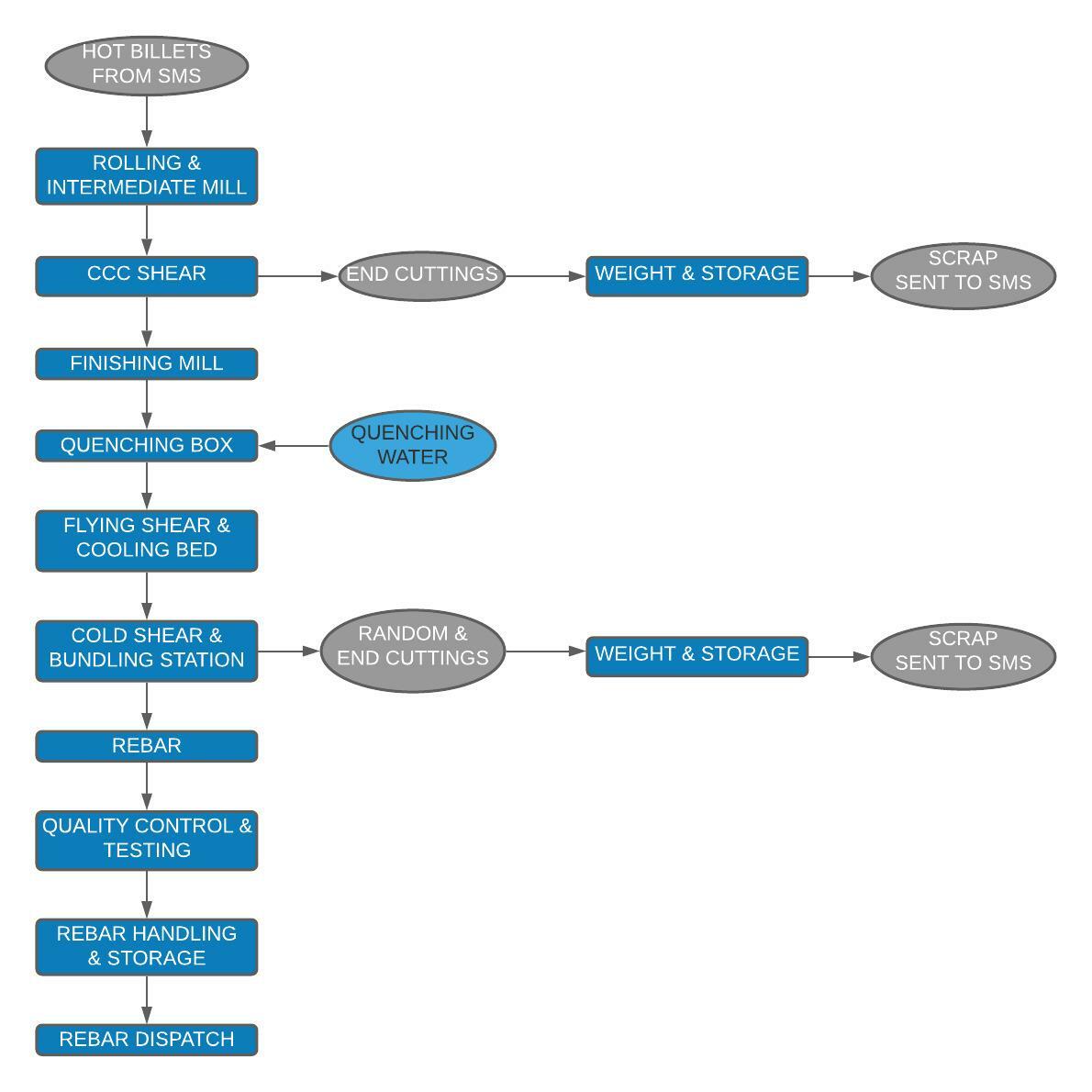

Rolling Mill - Process Flow Chart