SEIL's Steel Melt Shop has 4 Induction Furnaces each having a liquid steel production capacity of 25 tons, one 30 ton Ladle Refining Furnace and a three Stand, 4/7 Continuous Caster producing 100x100 and 110x110 MS Billets.

Process

The Sponge Iron from the day bins is conveyed to the operating platform of the Induction furnaces. The Scrap and Pig Iron is brought with the help of scrap bucket transfer cars and EOT cranes.

The furnace crucibles are lined with silica ramming mass and sintered at low power sintering panel to achieve the proper sintering of the lining material. The furnace crucibles are inspected before starting the furnace for the next heat.

The initial quantity of scrap and Pig Iron are charged into the induction furnace with the help of scrap transfer car or through electro magnets. After melting the initial charge, sponge iron is fed at a specified rate from sponge iron bits or through electro magnets. While melting the sponge iron, slag forms in the crucible at the top of the liquid metal and is removed at regular intervals by tilting the crucible.

Once the charge melts and the temperature reaches above 1650oC, bath sample is taken and temperature is measured. At this stage, the steel is ready for tapping. Liquid samples are collected for chemical composition analysis in the spectrometer before casting.

The liquid metal from the induction furnaces is then poured into a ladle by way of hydraulic furnace tilting arrangement. The ladle is then transferred to the LRF platform to maintain the necessary temperature and for refining. The liquid steel after addition of Ferro Alloys (Silico Manganese and Ferro Silicon), is lifted by EOT crane and placed on the ladle stand of the Billet caster.

In the meantime, a Tundish lined with cold insulating board and preheated nozzles and mounted on the Tundish car is moved from the nozzle preheating position to the casting position. The ladle slide gate is opened to allow flow of liquid steel into the Tundish. The liquid steel stream from the ladle to Tundish is protected by ceramic shroud to ensure superior quality of the cast product.

Prior to commencing casting, rigid dummy bars are introduced into the moulds. The gap between the dummy bar head and the mould walls are sealed with asbestos chord. Small pieces of steel scrap are placed over the dummy coil heads to chill the initial liquid steel. Water supply to moulds, secondary cooling zone and machine cooling are switched on. When the liquid steel level in the Tundish reaches a predetermined level, the nozzles of the Tundish are opened to let liquid metal flow into the moulds.

When the liquid steel level in the moulds reaches about 100-150 mm from its top, the drives of the mould oscillating mechanisms, withdrawal and straightening units are switched on. The withdrawal of the dummy bars begins at the minimum speed and gradually increases to normal casting speed within a few minutes. A requisite quantity of rapeseed oil is added to lubricate the mould walls.

The partially solidified strands after leaving the moulds pass through the strand guide system where intensive but controlled cooling of the strands is achieved by direct water spray nozzles. The solidified strands are guided through the withdrawal and straightening unit before the torch cutting zone. The dummy bars are separated from the cast strands when dummy bars reach beyond the withdrawal and straightening unit and stored in a dummy bar storage device till their introduction is required for the next cast.

The cast strands are cut into a predetermined length by automatic oxy-acetylene gas cutting torches. More than 85% of the cut billets, to be rolled by way of hot charging, are transferred to the Rolling Mill through inter bay roller table and the balance are transferred to the cooling bed through cross transfer. From the cooling bed, the billets are lifted by a billet handling magnet crane and stacked in the storage yard. For every heat, a sample is collected for laboratory analysis.

The Quality Assurance Plan (QAP) is ensured by the use of Spectrometer and chemical analysis to maintain the Carbon, Sulphur, Manganese, Phosphorus and other required elements within the specified limits as per the specification of Billets for making Rebar ( Grade 550/D, Grade 500/D and Grade HSCRM).

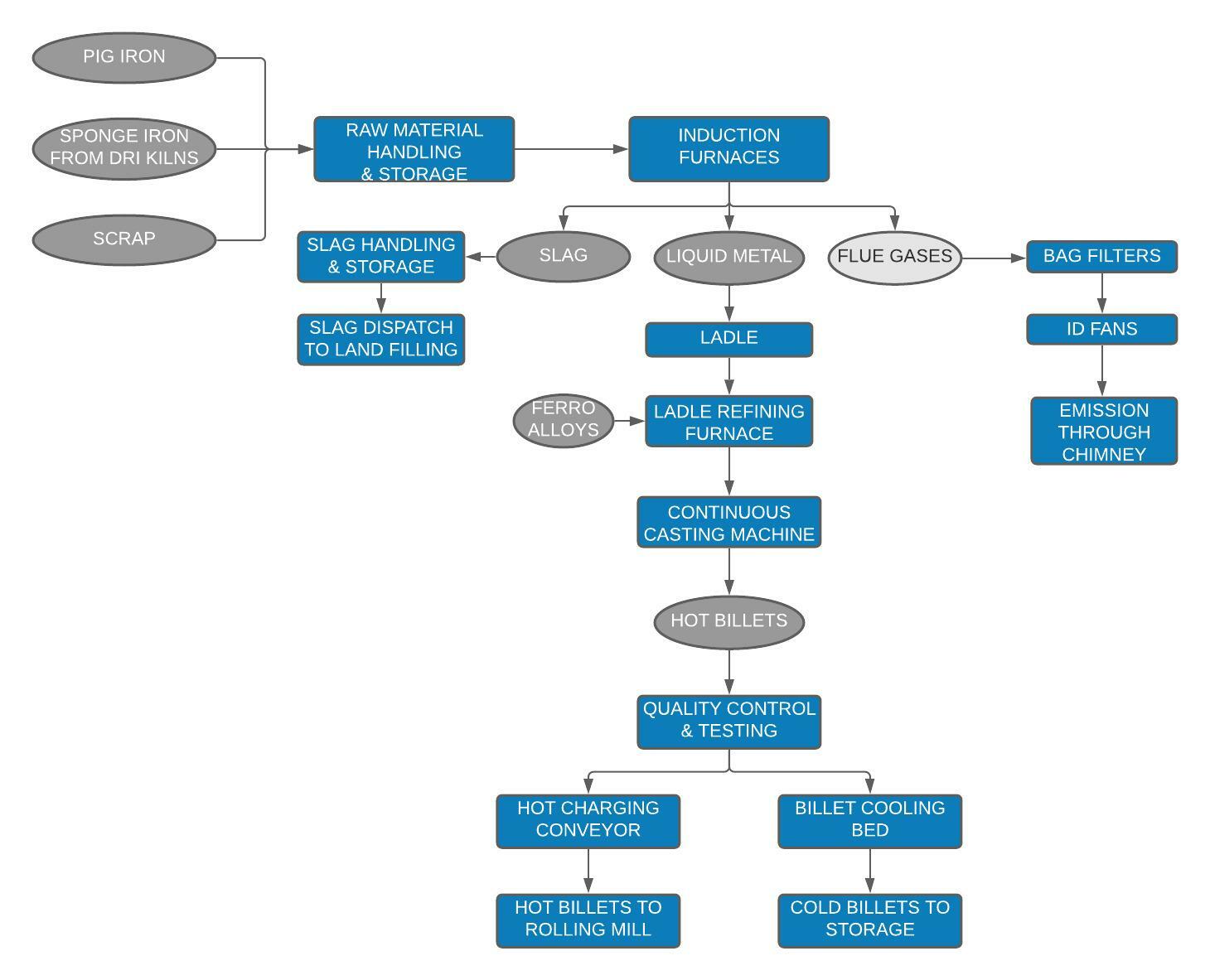

Steel Melt Shop - Process Flow Chart